.png)

Business Growth Tools

.png)

Business Growth Tools

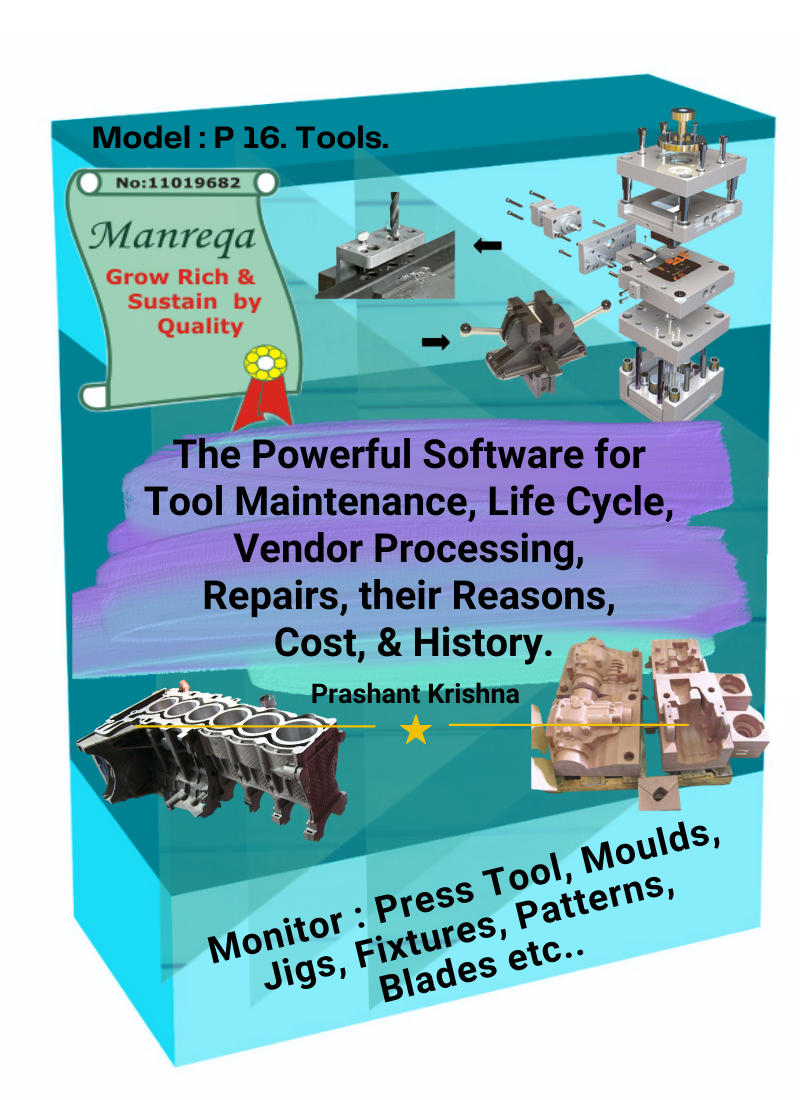

The Ultimate Module to Monitor & Control the Tools Like: Press Tool, Moulds, Jigs, Fixtures, Patterns, Blades etc. Prevent Losses for Repeat Repairs, Re -Processing On Tool Parts by Knowing the Reasons & Repeat Reasons.

Model Name: Tool Maintenance. Model: Number P - 16.

Price : ₹ 710=00 per Month, Per User, Paid on Yearly Basis ₹ 8,520=00.

D) ISO ERP Training:Yes : Only By Online Videos.

E) Installation Support:Yes : Online Support.

F) On Premises Training:1) On Premises Training is not Required as, ERP is Easy to Operate & Of course there are Plenty of ISO ERP Videos Available, so that Users Can Get Trained Themselves & Use the Software.

2) Client who Requires On-Site Training or Online Training Support, However, Must Pay an Additional Fee, which is Calculated Each Visit or Per Month. The Cost of Training Per Visit or Per Month is not Included in the Above Section - Srl No C) Cost.

Definitions & FAQ's:

1) What is Tool Maintenance?

2) What are Tools?

3) How Many Types of Tool?

4) What is the Purpose of Monitoring Tool Life ?

5) Why is Tool Maintenance Important?

6) What is Tool Maintenance Check List?

7) What are the Requirement of ISO 9001 2015 For Tool Maintenance?

8) Tool Maintenance is Addressed in Which Clause Number & Main Clause ISO 9001 2015.?

9) What are Tool Maintenance Formats?

10) What is Tool Maintenance ERP Software?

11) What is Tool Service Record?

12) What is Tool Service Schedule?

13) What is Tool Life & How it is Monitored?

14) How to Calculate the Tool Repair Cost, Tool Life & How to Monitored it?

15) How to Compare the Planned Tool Life to the Actual Life?

16) How to Know the Total Output of a Tool Before It Is Discarded?

17) What is Tool Master?

18) What is Tool Room Progress?

19) What is Tool Defect Report?

21) What is Tool Rectification Report Tracker?

22) What is Tool Life Repair Status Tracker?

23) How to Monitor Tool Life & its Repairs?

24) How to Monitor Tool History & Cost.?

25) How to Monitor the Life of a Press Tool?

26) What is a Press Tool?

27) How to Monitor the Life of a Jig?

28) What is a Jig?

29) How to Monitor the Life of a Mould?

30) What is a Mould?

31) How to Monitor the Life of a Fixture?

32) What is a Fixture?

33) How to Monitor the Life of a Pattern?

34) What is a Pattern?

35) How to Monitor the Life of Blades?

36) What are Blades?