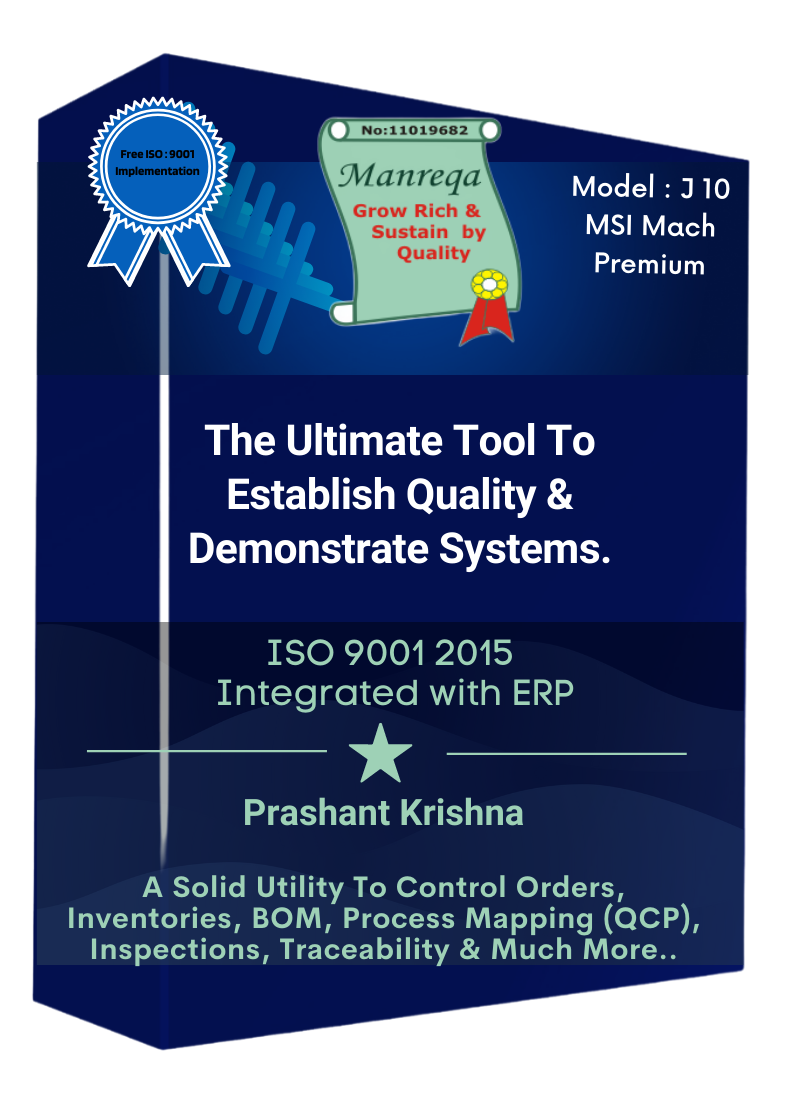

Model Name: MSI Mach Premium. Model Number: J – 10.

Low-Cost and Cost-Effective Best ERP for Indian SME's and small business owners: Manreqa ERP Software useful for:

- Investment.

- A desire to become a MNC.

- Dedicate time to understanding and practise.

- Utilize the tool to its maximum capacity.

- A management team that desires to oversee and manage the machine shop.

- Who desires to know the performance of the machinery?

- As a policy of management, each product, and each RM must have a QCP.

- No purchase order shall be issued without comparing prices with at least three suppliers.

- No bill shall be passed without the approval of the QA Incharge.

- Without a route card, no shift shall begin the manufacturing process.

- As a rule of management, drawings should be available for each step or processes involved in manufacturing of a part.

- As a management policy, unless a RM receiving inspection is carried out & recorded, no part shall be produced.

- Part inventory shall be online at any given point of time.

- Inventory RM must be available online at all points of time.

- Employees must be able to devote time each day to producing accurate data and maintaining records.

- A manufacturer that wants to prove that they produce quality products, & have systems that are practiced at any given point of time.

Computerize various departments with Manreqa ERP: The extent of computerization is described below:

- Marketing: Enquiry, Quotation, Order Acceptance (J 10).

- Incoming Register: Customer Order (A 1).

- Contract List: Order Acceptance (A 1).

- Supplier PO (Print of PO) (D 4).

- Supplier GRN (Print of GRN) (D 4).

- Vendor (Print of DC) (D 4).

- Vendor GRN (Print of GRN) (D 4).

- Drawing Register (D 4).

- QCP (D 4).

- CAR (D 4).

- Customer Feedback (D 4).

- Calibration Status (E 5).

- Related MRM Analysis & Graphs (D 4).

- Report Module. Data by Reports I.e. Status Reports. (C 3).

- Single BOM (F 6).

- The Production Scheduling - Stock (J 10).

- Manufacture Route Card Print Production Planning (I 9).

- Production Progress (I 9).

- Inprocess & Final Inspection (I 9).

- Sales Invoice (I 9).

- Scan Documents & upload in ERP. (J 10).

- Marketing Module (J 10).

- Comparative Analysis systems (J 10).

- Machine Maintenance, Repairs, Expenses & History Card (J 10).

- Tool Maintenance, Expenses & History Card. (J 10).

- Instrument Status, Calibration, Expenses & History Card (J 10).

- Trackers (J 10).

- Traceability RM Batch & or Product Batch (J 10).

- Control Access: Per Screen Per User/Person (J 10).

- To Know the Exact Scope for this Software Model, Please Register & Free Download of A Demo Scope Video Which is Above in The Rectangle Product Box, or Download Free Complimentary Manreqa ERP Software.

Subscription Cost or Manreqa ERP Software Pricing:

Price : ₹ 2,899.00 per Month, Per User, Paid on Yearly Basis ₹ 34,788=00.

Get attractive discounts for a minimum of 5 users, with different pricing structure that have 30% Subscription Licenses fee on yearly basis.

ERP Training:

Yes : Only By Online Videos:

ERP Installation Support:

Yes : Online.

Manreqa ERP Online Training:

1) Online training is not required, as ERP is easy to use and there are plenty of ERP videos available for users to train themselves on how to use the software.

2) For clients who need online training, additional fees will apply, ranging from per-week training fees to the monthly training fee. The cost of online training is not covered in the section titled "Price or Cost of Manreqa ERP Software" above.

Definitions & FAQ's:

1) What is a Route Card?

2) What is a Product or Part?

3) What is a Raw Material ?

4) What is a Final Inspection?

8) What is Production Scheduling Stocks?

5) What is Scrap?

6) What is Tool History?

7) What is Tool History Card and why it is Essential?

8) What is Machine Maintenance & its History?

9) What is Machine History Card and why it is Essential?

10) What is Instrument History?

11) What is Instrument History Card and why it is Essential?

12) What is Inspection?

13) What is Tracker?

14) What is Marketing: Enquiry, Quotation, Order Acceptance?

15) What is Machining Industry?

16) What is Label Printing Industry?

17) What is Injection Moulding Industry?

18) What is Die Casting Industry?

19) What is Tracker?

20) What is Extrusion Industry?

.png)

.png)