.png)

Business Growth Tools

.png)

Business Growth Tools

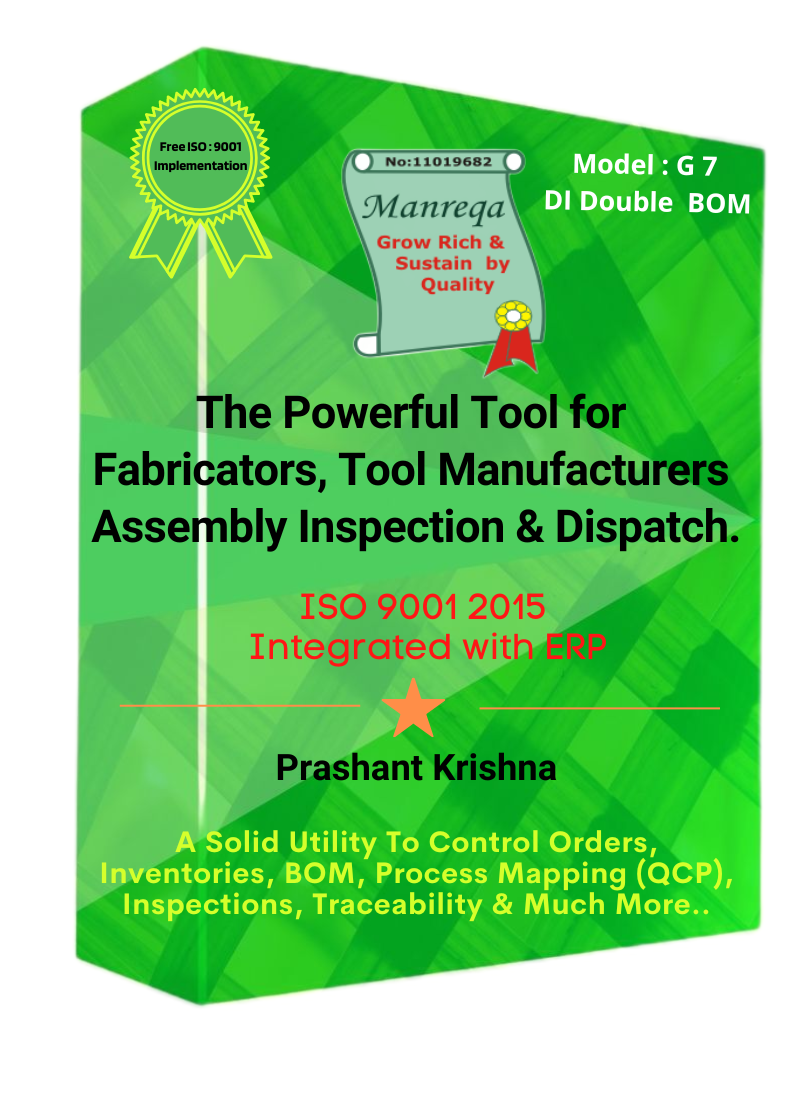

The ultimate tool for fabricators and tool manufacturers to capture raw materials, component parts, subassemblies, and final product assembly systems. Auto-deduction or let off RM inventory based on the BOM.

Model Name: DI-Double BOM. Model Number: G – 7.

Price : ₹ 2,065.00 per Month, Per User, Paid on Yearly Basis ₹ 24,780=00.

Total Amount with 18% GST : ₹ 29,240=00.

Get attractive discounts for a minimum of 5 users, with different pricing structure that have 30% Subscription Licenses fee on yearly basis.

Yes : Only By Online Videos:

ERP Installation Support:Yes : Online.

Manreqa ERP Online Training:1) Online training is not required, as ERP is easy to use and there are plenty of ERP videos available for users to train themselves on how to use the software.

2) For clients who need online training, additional fees will apply, ranging from per-week training fees to the monthly training fee. The cost of online training is not covered in the section titled "Price or Cost of Manreqa ERP Software" above.

Definitions & FAQ's:

1) How do you define inventory?

2) What is a Child Part?

3) What is a Sub Assembly?

4) What is a Welding Process?

5) What is Fabrication?

6) What is Metal Fabrication?

7) What is Metal Fabrication ERP?

8) What is Steel Fabrication Management Software?

9) What is Bill of Material in Metal Fabrication?

10) What is MS-Mild Steel & SS-Stainless Steel Fabrication Industry?